Arrowhead vs other breaker designs

When Ironhawk was offered the opportunity to represent and sell Arrowhead attachments in NZ, it was a "no brainer". We had done our research on the brand, the design, and the history so it was an easy decision and fitted well with our way of thinking. Ironhawk only deals with high quality equipment and our customer base appreciate the long term cost effectiveness of buying the best which reduces the down time caused by cheaper products.

Arrowhead vs other breaker designs

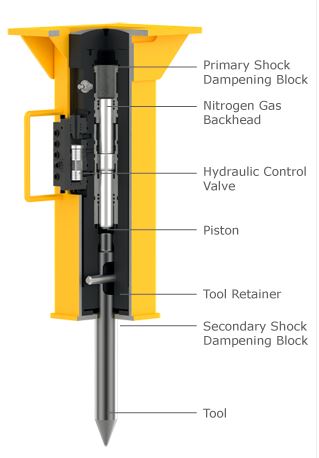

The mainstream style of breakers use the traditional tie rod design. This design usually involves four long tie rods which run down each corner of the hammer and they can be prone to fatigue and breaking which can result in extra repair costs down the road. Arrowhead R series breakers do not have these moving rods in them so are a better, more reliable design.

The R Series breakers get all of their impacting power from a nitrogen gas backhead at the top of the breaker, when the oil comes in from the excavator, it lifts the piston up into the gas backhead which compresses the gas and then, when the oil leaves the breaker, the compressed gas acts basically like a giant spring and pushes the piston back down onto the tool producing the impacting force of the breaker.

This means the Arrowhead breaker has the same power in each blow and is very consistent. Because we only use high pressure oil on the lift stroke of the piston we can have a very simple valve system so in any of our breakers there are only 3 moving parts, consisting of the main piston which strikes the tool and 2 pistons in the valve block. Less moving parts reduces wear, reduces energy loss, and improves reliability.

The R series breakers are enclosed in a one piece casing and inside this casing, at the top and bottom there are 2 polymer isolator buffers. These buffers mean that there is no direct metal to metal contact between the breaker body and the yellow casing. this design feature has a significant effect in reducing the vibration from the breaker which will help to protect your excavator as there will be less wear on the pins and bushings in your excavator boom arm.